Leather is perhaps one of the most popular, sought after material for shoes, bags, wallets, and watch straps and has garnered a lot of attention for years and years.

While the most common types of leather like cowhide, goat hide, sheep hide are affordable and cheap, I set out on a research quest to find out which is the most expensive leather and here’s what I found.

So, which Leather is the most expensive? Shell Cordovan is the most expensive leather in the world because it is scarce since only a few places in the world raise horses for food and leather plus, it’s very difficult and expensive to make. The tanning process of Shell Cordovan can take up to 6 months to complete.

Shell Cordovan has so many great qualities beyond what has been mentioned above that makes it the most expensive leather in the world today. Keep reading to find out more!

Why is the Shell Cordovan so Expensive? Really!

Before we move on to the reasons for Shell Cordovan being expensive let’s first define what it is.

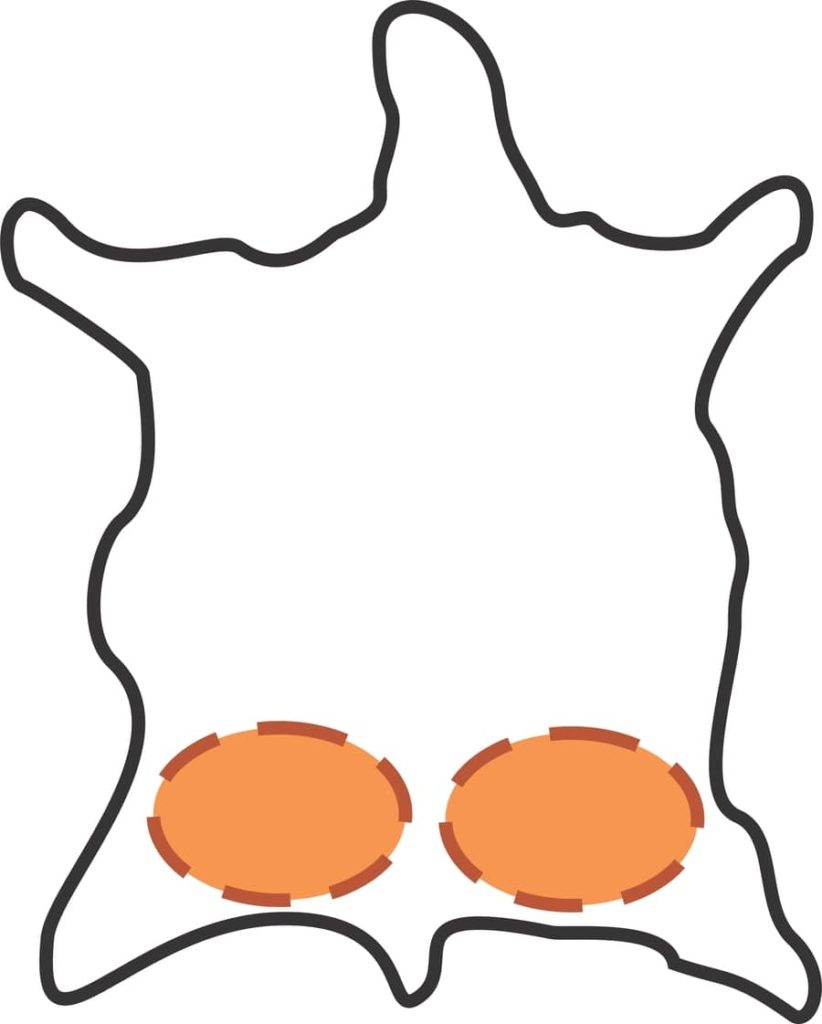

What is Shell Cordovan? Known as the King of Leather, Shell cordovan is leather derived from the flat muscle below the hide on the rump of horsehide.

Now to the reasons why Shell Cordovan is the most expensive leather in the world!

1. The Raw Hide of Horse is Scarce

The high price of shell cordovan is a result of the low supply of the horsehide while demand for it is high. Compared to cow, sheep, and goat, the breeding of horses for food is only done in a few countries worldwide.

Equine domestication began to raise horses for food, but the practice became controversial in parts of the world due to concerns like the safety of the meat and the perception that horses as pets or gods.

On top of all the talk of the scarcity of horsehide, when it is obtained only a small part (the rump or butt area) of the horsehide can be used as shell cordovan leather.

Due to the structure of the rump of the horse, it can’t be split into layers like the hide obtained cow.

So, the supply of horsehides is really small and has seen no growth for a long time. These are the contributing factors to how rare this hide is and the high price people have to pay for the leather.

2. Very Long, Complicated, and Expensive Tanning Process

The process of turning the raw hide from horse into a shell cordovan is pretty much lengthy because the vegetable tanning method is often used in its tanning process.

The vegetable tanning requires using tannins from plant extracts to tan leather.

Plus tanning horsehide is a very gentle and patient process so as to allow the tannins to penetrate the dense membrane of the horsehide.

3. Has a Membrane instead of Fibers

The shell cordovan has a membrane instead of the regular fibers you would see most leathers with. This makes it extremely durable, wrinkle-resistant, and water-resistant.

Instead cordovan wrinkling, it ripples. This makes a great deal of difference because in leather wrinkles usually result in cracks.

Also, with its pores being of the shell cordovan so dense its makes it perfect water and stretch-resistant material.

4. Ages Exceptionally Well

Shell Cordovan ages particularly well as it develops a beautiful patina over time. The more it’s used the more beautiful it becomes and a well-cared-for shell cordovan leather item like bag or shoes can truly last you a lifetime.

5. Classic Range of Colors

The Shell Cordovan leather due to its dense pores doesn’t allow it to accept dye very well. You can only get shell cordovan in dark shades of brown, black and the staple dark burgundy rose color.

History of Shell Cordovan

The history of leather dates back to prehistoric men who covered first themselves with pieces of leather but the first talk of horse leather was in the 7th-century Spain by the Visigoths and later the Moors.

This type of leather, Shell Cordovan, derived its name from the city of Cordoba which is noted for leather tanning.

Towards the 17th century, leatherworkers decorated horse leather goods like shields, armor, wall hangings of which some can still be found in museums today.

German and Dutch tanners arrived in the United States to trade for polished cordovan termed “spiegelwahre”. The name literarily translated as mirror ware due to cordovans’ mirror-like finish.

Shell Cordovan in the 19th Century was marketed for its durability, thickness, and toughness rather than its looks.

It was often used as leather razor strops until the development of safety razor during world war 1.

The tanning techniques for shell cordovan was further improved in the 20th century by American tanners. They made the shell cordovan leather more supple and softer and became a common material for making shoes.

Today, the traditions of Cordovan leather is still being maintained by artisans like Meryan in Cordoba.

Tanning Process of Shell Cordovan Leather

The tanning process of the shell cordovan is really complex so I will break it down into simple digestible points for you.

- Only a few tanneries in the world still produce Shell Cordovan leather. For example, Horween, USA.

- There are over a hundred processes involved in the tanning process and can take up to 6 months to complete.

- The aim of the tanning process is to stop decay and make it leather-like

- The process begins with the salted horse hides sourced popularly from countries like France.

- The salted horse hides arrive in pallets and the butt area is then cut by hand.

- The horsehide undergoes vegetable tanning where plant extracts like chestnut and quebracho tree bark and resins are used. The tanning is done in pits and agitated to ensure the hide is evenly tanned.

- The tanning process is really gently to ensure the tanning agents penetrate deeply into the hide.

- After 30 days, the hides are removed from the pits and shaved to reveal the shell.

- The hides then go back into another pit with much strong solution for another 30 days

- After the 30 days, the hides are removed and rinsed with water in a giant revolving tank.

- From here there is about 4 months’ worth of work remaining.

- The leather is removed and dried.

- When the leather is dry, an expert handpicks each hide and carefully trims off the parts around the butt (The Cut-offs are sold as horsehide strips).

- The hides are polished or colored.

- The final stage is to allow the hides to rest for a few weeks

Watch a video on How the Shell Cordovan leather is Made

Pros and Cons of Shell Cordovan Leather

Pros:

- Durable

- Water-Resistant

- Develops Patina

Cons:

- Very Expensive

- Many people do not find beauty in how Cordovan ripples

- Limited range of colors

Conclusion

The Shell Cordovan leather is a great piece of leather material with great qualities that have made it attained its accolade as the king of leather. However, while others may be able to afford a piece of a leather item made from Shell Cordovan, others might not but can still enjoy the countless other kinds of natural leathers.

Related Questions

Why is leather expensive? How expensive leather or leather products are depends on the types of animal leather; exotic leather is much more expensive, and the grade of the leather; full-grain and top-grain leather are very expensive.

Which other leather apart from Shell Cordovan is most Expensive? The other types of leather that are also very expensive apart from shell cordovan are Nappa Leather, Nubuck leather, Suede, and Brushed leather.